Stainless Steel

Post

Tensioning

Bar

Excellent

Fatigue

Resistance

Stainless

Steel

Post

tensioning

system

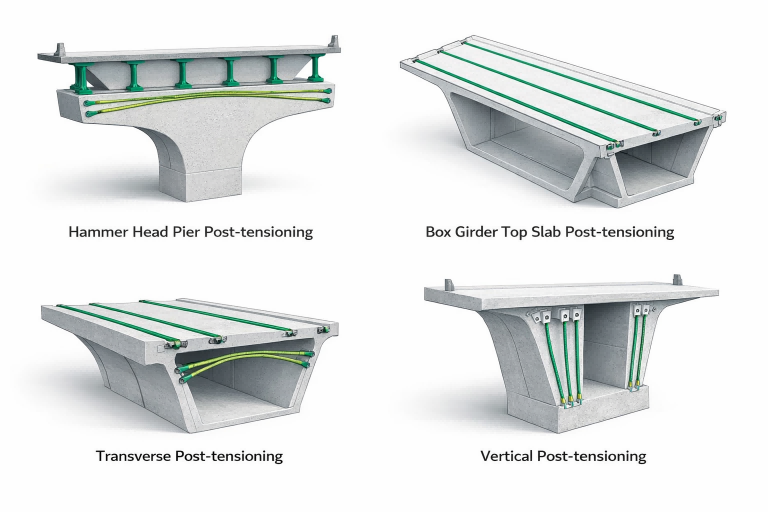

Post-tensioning bar(PT Bar) is a material used to reinforce concrete structures. Usually, it is a round plain steel bar, after applying pre-stress, is anchored in the concrete structure using anchoring devices. Post-tensioning bars are commonly used in bridges, floor slabs, foundations, and other concrete structures to increase their load-bearing capacity and seismic performance. The Fusteel PT bar is made of stainless steel which have high strength and excellent corrosion resistant properties.

The stainless steel post-tensioning system is engineered from heat-treated 17-4PH stainless steel,ensuring exceptional strength exceeding 1030MPa.

stainless steel post-tensioning system is engineered from heat-treated 17-4PH stainless steel,ensuring exceptional strength exceeding 1030MPa.

The

stainless steel post-tensioning system is engineered from heat-treated 17-4PH stainless steel,ensuring exceptional strength exceeding 1030MPa.

stainless steel post-tensioning system is engineered from heat-treated 17-4PH stainless steel,ensuring exceptional strength exceeding 1030MPa.

It

works good

Renowned for its resilience and longevity, stainless steel post-tensioning system offer numerous advantages:

stainless steel post-tensioning system offer numerous advantages:

stainless steel post-tensioning system offer numerous advantages:

stainless steel post-tensioning system offer numerous advantages:- Corrosion Resistance: 17-4PH stainless steel's inherent corrosion resistance ensures longevity in various environments, including those with high moisture or chemical exposure.

- High Strength: The heat-treated 17-4PH stainless steel composition endows the post-tensioning system with remarkable strength, exceeding 1030MPa, ensuring structural integrity and reliablity.

- Fatigue Resistance: 17-4PH stainless steel's superior fatigue properties make it ideal for applications subjected to dynamic loads and prolonged stress,minimizing the risk of structural failure over time.

- Dimensional Stability: 17-4PH stainless steel maintains its shape and structural integrity under various temperature fluctuations, ensuring consistent performance over the long term.

- Versatility: Available in diameters ranging from 20 to 75mm and lengths of up to 6m, with options for longer lengths achieved through coupler-assisted extensions,

stainless steel post-tensioning system cater to diverse prject requirements.

stainless steel post-tensioning system cater to diverse prject requirements. - Ease of Installation: Coupler-assisted extensions facilitate seamless integration and assembly, streamlining the installation process and reducing construction time.

- Customization: Custom sizes are available upon request, ensuring that the post-tensioning system meet the specific needs and specifications of each project.

| Nominal Diameter(mm) | Nominal Cross Sectional Area(mm²) | S1030 Mass (kg/m) | Major Diameter of Threads(mm) | Minimum Hole Diameter in Steelwork(mm) |

|---|---|---|---|---|

| 20 | 315 | 2.46 | 22.0 | 24 |

| 25 | 491 | 3.83 | 28.9 | 31 |

| 26.5 | 552 | 4.31 | 30.4 | 33 |

| 32 | 804 | 6.27 | 36.2 | 40 |

| 36 | 1018 | 7.94 | 40.2 | 44 |

| 40 | 1257 | 9.80 | 45.3 | 49 |

| 50 | 1963 | 15.31 | 54.8 | 59 |

| 75 | 4185 | 32.64 | 77.2 | 82 |

| Grade |  S1030 |

|---|---|

| Charadteristic Ultimate Tensile Strength (N/mm²) | 1030 |

| Minimum 0.1% proof Stress (N/mm²) | 835 |

| Minimum Elongation (%) | 10 |

| Approximate Modulus of Elasticity (N/mm²) | 185 |

Fusteel Co., Ltd. © 2023, All rights reserved

We would like to use cookies to better understand your use of this website. We only capture your page views, which will help improve your experience the next time you visit this website. If you click the confirmation button on the right, you will be deemed to agree to the use of cookies.

acceptreject